main.content

Engineering services for industrial production

As a specialised provider in the field of electrical connection technology, we offer comprehensive engineering and development services for the industrial production of connection elements. Our aim is to optimise customer-specific drawings and technical concepts in a targeted manner in order to ensure efficient, cost-effective and series-ready production.

Our range of services includes the precise customisation of design solutions, the selection of high-quality, application-specific materials and the integration of advanced manufacturing technologies into existing production processes.

Thanks to our many years of experience and our in-depth expertise in electrical connection technology, we are able to further develop existing product designs so that they fulfil the highest quality standards and at the same time enable significant savings in production costs.

-

Industrial design with a focus on design-for-manufacturing (DFM)

A well thought-out design determines the subsequent economic efficiency. With our industrial design, we combine aesthetics with component optimisation and ease of production.

Thanks to our expertise in design-for-manufacturing (DFM), we optimise your products in the early stages - tailored to injection moulding, stamping and bending technology, additive manufacturing technologies and many other processes.

The result: technically mature and cost-efficiently producible components, ideal for series production or engineering for small series production.

Our focus is on:

-

Production-orientated design that simplifies production processes and reduces costs

-

Reduced complexity to minimise processing effort and rejects

-

Material efficiency through targeted material selection and well thought-out design

-

Ease of assembly to avoid reworking and manual intervention

-

Series stability so that high quantities can be realised with consistent quality

-

-

Applications

-

Customised solutions

A key component of our services in the field of electrical connection technology is the close, partnership-based cooperation with our customers. We analyse all the requirements and technical specifications of a project in detail in order to develop customised solutions that are precisely tailored to individual needs and operating conditions.

Our focus is not only on the maximum functionality and reliability of the fasteners, but also on optimising the entire production process. Through our customer-orientated approach, we create the basis for efficient, sustainable and economical series production.

-

Technological innovation

In order to always deliver top performance in electrical connection technology, we rely on state-of-the-art technologies and continuously invest in the further training of our team. In this way, we ensure that our engineering services are always state of the art.

This forward-looking approach allows us to develop innovative solutions, recognise technological trends at an early stage and give our customers a sustainable competitive edge - both in terms of product quality and the efficiency of their manufacturing processes.

-

Technical competitive strength

Rely on our many years of expertise in electrical connection technology to optimise your products specifically for industrial production. With a clear focus on efficiency, quality and cost-effectiveness, we support you in strengthening your market position in the long term.

Together, we develop solutions that are not only technically convincing, but also optimally tailored to your production requirements from an economic point of view for long-term and measurable competitive success.

-

Additional optimisation methods

To maximise precision and production quality in electrical connection technology, we rely specifically on supplementary analysis and production technologies. These advanced methods not only guarantee the optimum manufacturability of our components, but also increase their performance in series production.

By combining sound engineering expertise, intelligent automation and state-of-the-art testing technology, we create the basis for economical, flexible and future-proof production. Our optimisation approaches enable connection solutions that meet the highest industrial requirements in terms of efficiency, precision and sustainability.

-

Vibratory grinding and finishing

To improve the mechanical and functional properties of our fasteners, we rely on precise surface finishing and vibratory grinding processes. These processing methods ensure uniform edge rounding and a smooth, resistant surface. The result: components with an improved feel, increased durability and optimised accuracy of fit for subsequent assembly and production steps.

-

Heat treatment

We use state-of-the-art heat treatment technology to optimise the physical properties of our fasteners in a targeted manner. Depending on the area of application, we enable increased strength, improved electrical conductivity or special material hardness through targeted temperature control. In this way, we ensure that each component is precisely designed for its load requirements - for maximum reliability in industrial use.

-

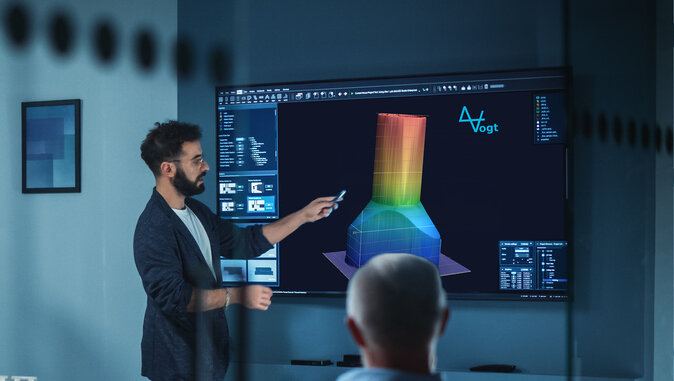

3D printing and prototyping

Our additive manufacturing range is the ideal complement to traditional component production. Using 3D printing technology, we realise precise prototypes and functional small series in the shortest possible time - quickly, flexibly and cost-effectively. This means that designs can be tested, adapted and made ready for series production at an early stage without having to put up with long development cycles. Ideal for customised requirements and dynamic development processes.