main.content

-

-

High-quality components for HB-Therm temperature control units

Temperature control units are used in injection moulding to adjust the temperature of the moulds to the respective plastics in order to achieve the highest possible part quality. HB-Therm, the world's leading manufacturer of temperature control units, has launched a new range of units onto the market with the Series 6.

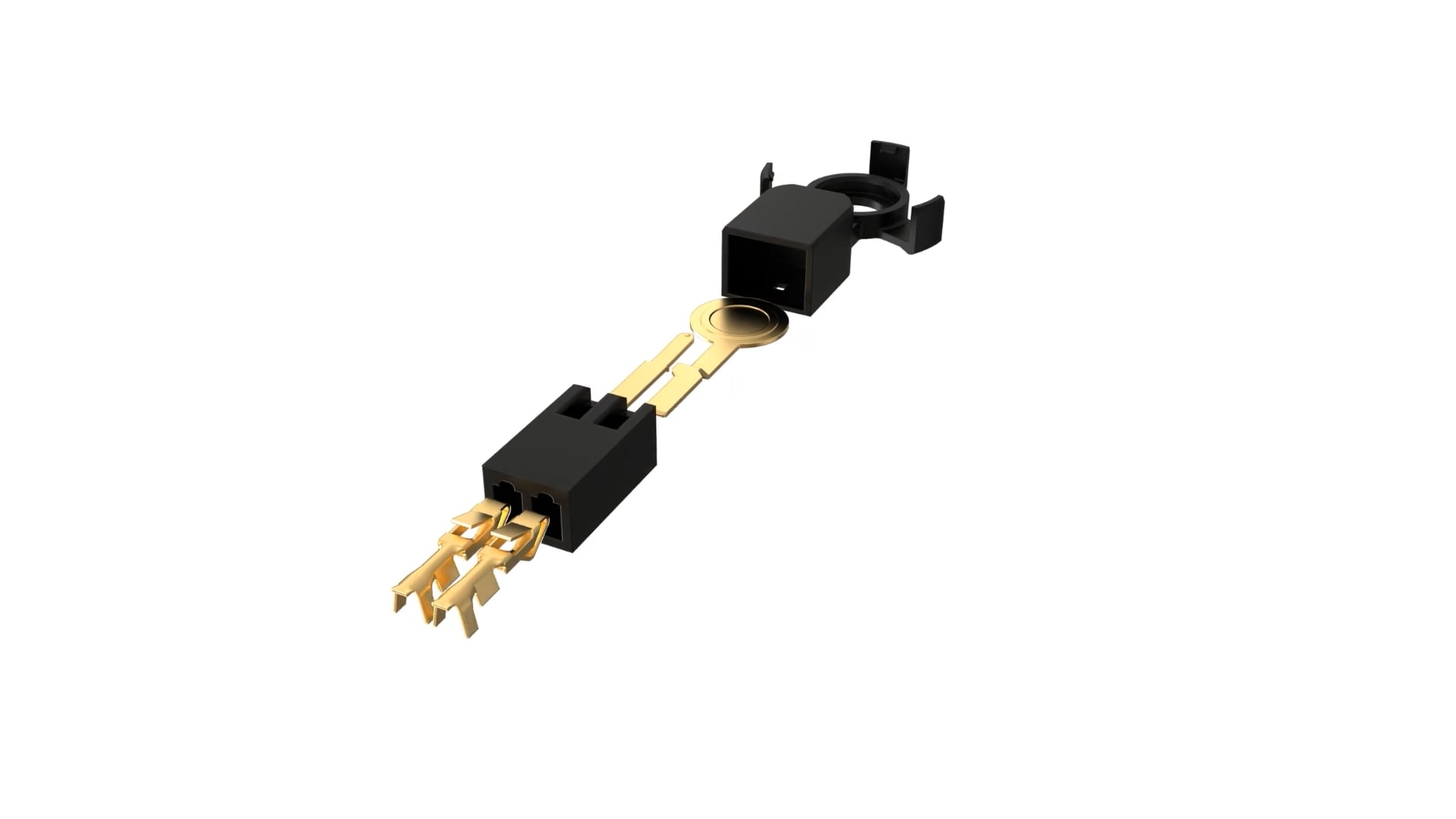

The Thermo-6 temperature control units contain a complex assembly and a connector housing from Vogt AG Verbindungstechnik, which was developed in close co-operation with the customer. The transducer is an important component of the ultrasonic technology used for piezo flow measurement. The intelligent device control measures and regulates the temperature up to 230 °C and the flow rate of the heat transfer medium continuously and with high precision.The gold-plated stamped parts of the transducer have high conductivity and are protected against corrosion, which contributes to a longer service life of the function and fulfils the required quality standards of the temperature control unit manufacturer. Our production includes the production of parts from toolmaking to stamping and injection moulding. Our quality management has first-class technological testing methods to ensure the quality of series production.

Both of the components we produce are part of the flow meters in the Thermo-6 temperature control units, for which HB-Therm offers a unique lifetime guarantee. The technology leader focuses on high quality and durability when it comes to procurement.