publiziert am 06. June 2023

Our new fully automatic blister machine LISA blisters up to 1,200 parts per hour. It uses SCARA robots to pack filigree, small parts into the blister belts provided for automatic further processing. Its speciality is SMD parts, but it also covers other areas of application and can be used universally for stamped and bent parts. With various optional modules, such as the Any Feeder, we can respond to the different needs and products of our customers. The standardised modules... View Article

publiziert am 20. March 2023

As a specialist in plastic injection moulding, Vogt AG Verbindungstechnik uses additive manufacturing to meet the growing demands and fast pace of the industrial sector. When customers come to us wanting to develop a product, we help them right from the outset in identifying the ideal solution in electromechanical press-fit technology. We simplify the realisation of customer projects by using state-of-the-art 3D printing technology, where components are formed layer by layer. We establish the project’s feasibility through rapid prototyping, which... View Article

publiziert am 20. March 2023

To mark its 60th anniversary, Vogt AG Verbindungstechnik opened its doors, on 25 June, to give the general public a look behind the scenes of its manufacturing and office facilities. Photos of the event in our Gallery. At the end of the tour, visitors were invited enjoy some delicious chilli con carne, hot dogs and sweet treats in the marquee. It had already been announced that all the proceeds were going to a good cause, and that a tree would be... View Article

publiziert am 26. October 2021

High precision and absolute reproducibility. Since the beginning of September, our plastics injection moulding department has been equipped with a further rotary injection moulding machine. Thanks to the different configuration options of the rotary table stations with two mould bases, our new injection moulding machine. can be used to respond quickly and flexibly to different customer requirements – our customers benefit from shorter cycles and production times. A state-of-the-art control and operating system with a large data set directory allow... View Article

publiziert am 23. August 2021

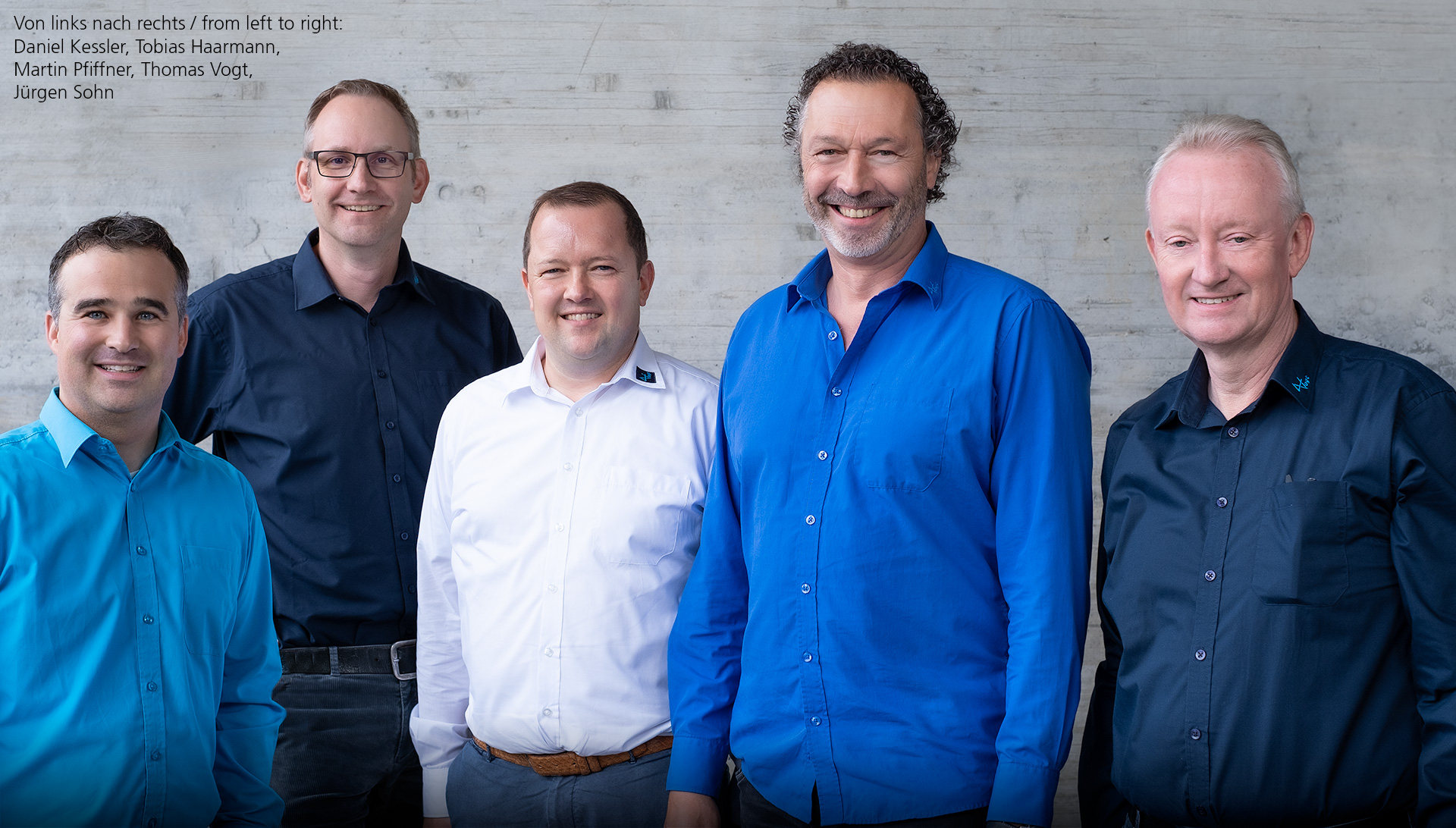

With the appointment of Martin Pfiffner as Head of Technology and Sales, we gained a specialist with technical and business experience. His extensive industry experience spans various complex sectors. Innovative and competitive products in the spheres of stampings, tubular and wire part production, as well as the specialist area of plastic hybrid parts, will be determined and developed under his management. Tobias Haarmann has already been successfully working in the company as Head of Product Management since May 2019 and,... View Article

publiziert am 22. July 2021

Refining parts produced is a crucial key element of connection technology, especially in the field of electronics. We do most of the post-processing of parts ourselves, for example edge rounding or soft annealing. For surface treatment, we depend on the expertise of our electroplating service provider who meets our high quality standards. Communicating with the electroplating business guarantees that our precision parts benefit from the best possible post-processing and functionality. Visits to the company and on-going training by our suppliers... View Article

publiziert am 14. June 2021

Technical support is not just required for customer-specific products. As the following example shows, the service we provide at Vogt AG Verbindungstechnik also includes advice and support with the standard product range. A customer contacted Vogt AG Verbindungstechnik because he was no longer able to find any spare parts on the market for his old crimp machine. During a phone call with the customer, we discussed how the spare part, a crimping tool, needed to be used for various receptacles... View Article

publiziert am 07. June 2021

Vogt AG Verbindungstechnik is digitally equipped for both feasibility studies and perfection of parts in mass production and has introduced a simulation tool (Mold Flow) for plastic injection moulding. The Mold Flow Analysis determines the feasibility at an early stage of development. The most important phase in injection moulding is the mould filling; this is decisive for the quality. The parts to be produced are digitally reproduced in an injection moulding tool. The simulation then examines how the plastic melt... View Article

publiziert am 13. April 2021

Technology inspires me and I want to bring successful products to the market. Innovation and entrepreneurship are my passion. Convinced customers, motivated employees and the company’s success are always my focus. With my technical and business know-how, over the last 20 years I developed many successful products. My experience in industry contains household appliances, biotechnology and medical technology, heating technology, sensor technology and mechanical engineering. In each case, the focus has been on standard products, but above all on development... View Article

publiziert am 30. March 2021

Our counting department has received reinforcements in the form of the Paxmatic multi-counter, a high-speed counting machine that can count several hundred parts precisely within a few seconds. The optical counting system with integrated 3D high-speed cameras can feed and detect parts in sizes from 0.5 mm to 25 mm. Any foreign parts are recognised and the machine is stopped. All Vogt items, regardless of whether they are wire end sleeves or complex hybrid parts, can be fed in and... View Article